What we do

Makes containers smart and chemical handling safe. For more sustainability across the entire supply chain.

learn more →

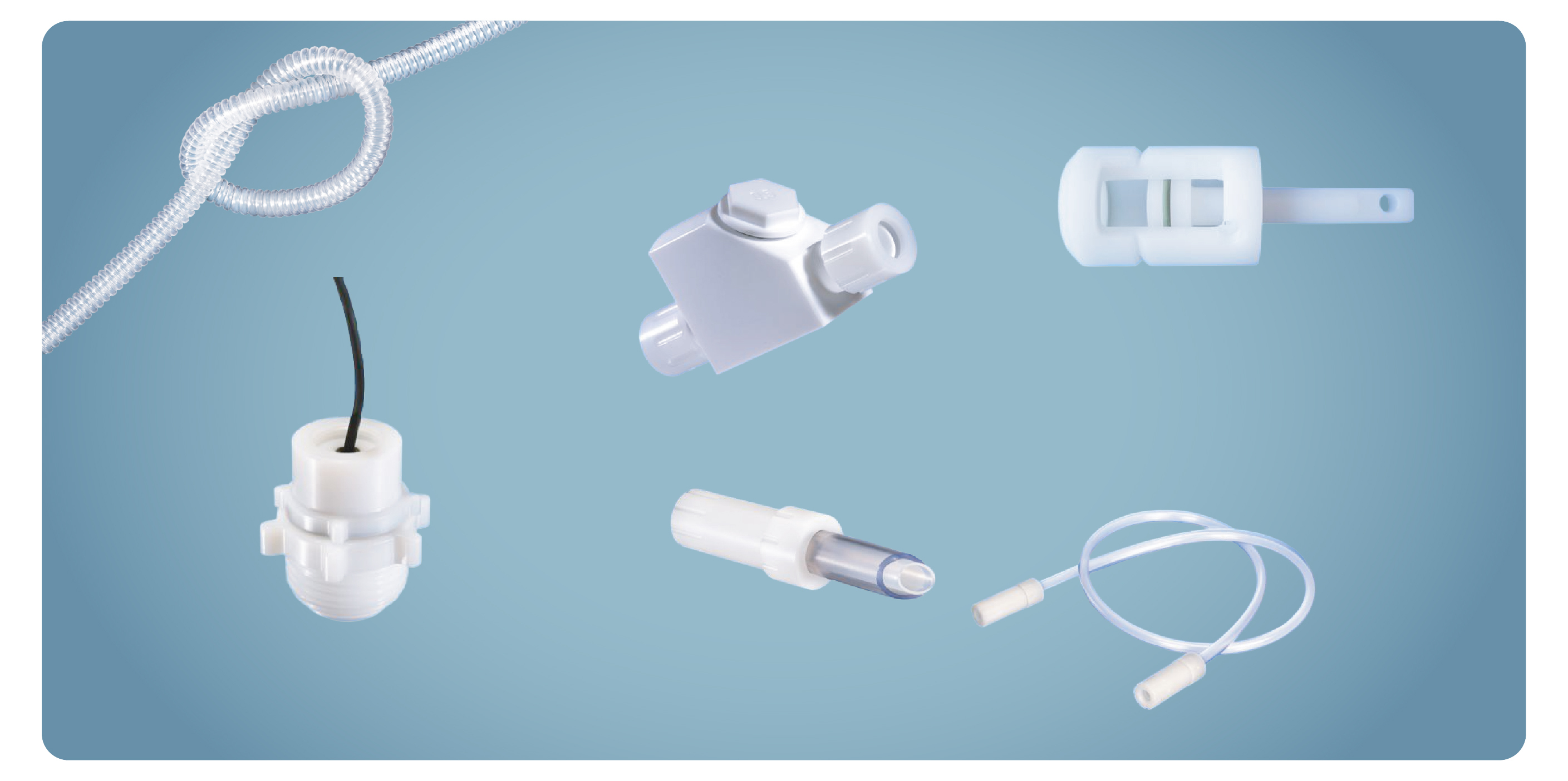

We develop and produce fittings, devices and valves from ultrapure plastics. Many customised solutions have developed into standard products over the years.

learn more →

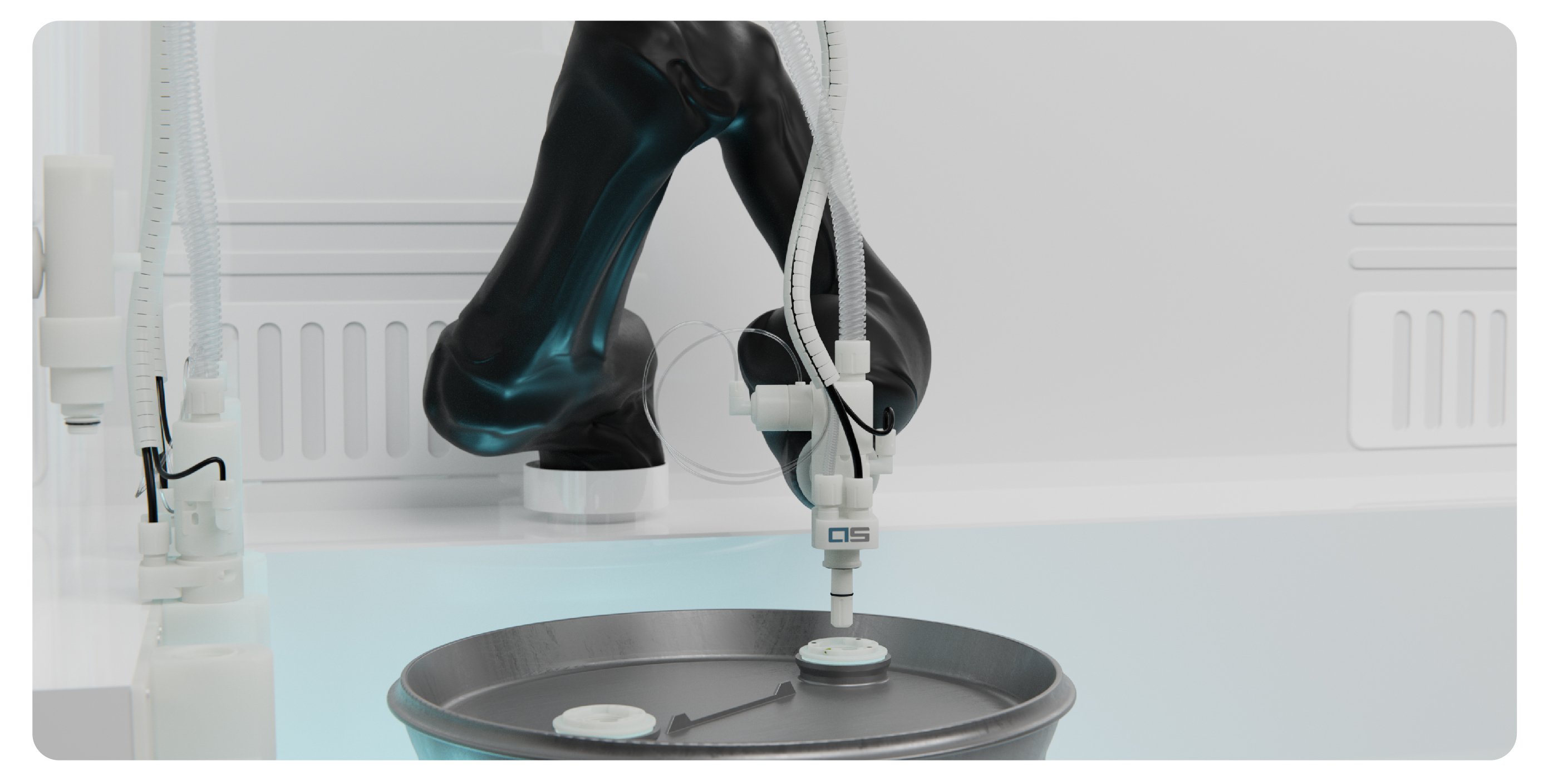

Play it safe with your robot colleague! Where yesterday people came into contact with extremely hazardous chemicals on a daily basis, a QC-Robot from AS is now doing its job.

learn more →Share your experiences with us!

In addition to the standard portfolio, individual components are produced in small batches as well as in large quantities from high-performance plastics in precision manufacturing.

Close to the customer: as a partner and “co-thinker”, rather than a mere supplier, AS is valued worldwide.

Over 35 years of experience in the industry help enormously - for quick, sometimes unusual, but always practical solutions.

Send us your questions or requests directly - simply email us using the button.

We will get back to you as soon as possible.