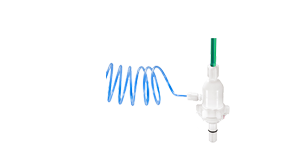

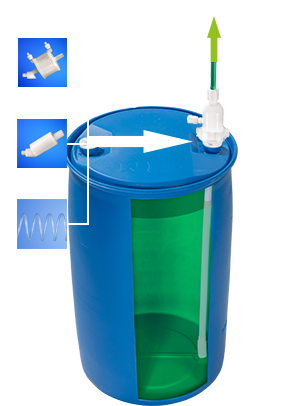

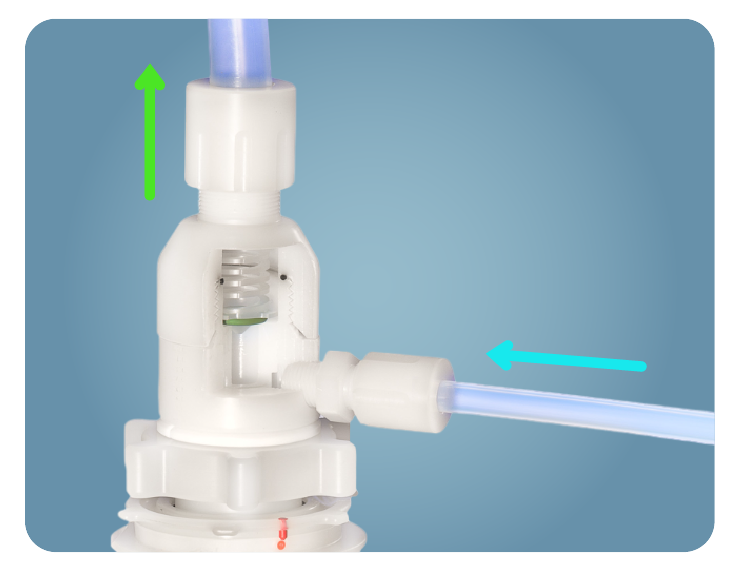

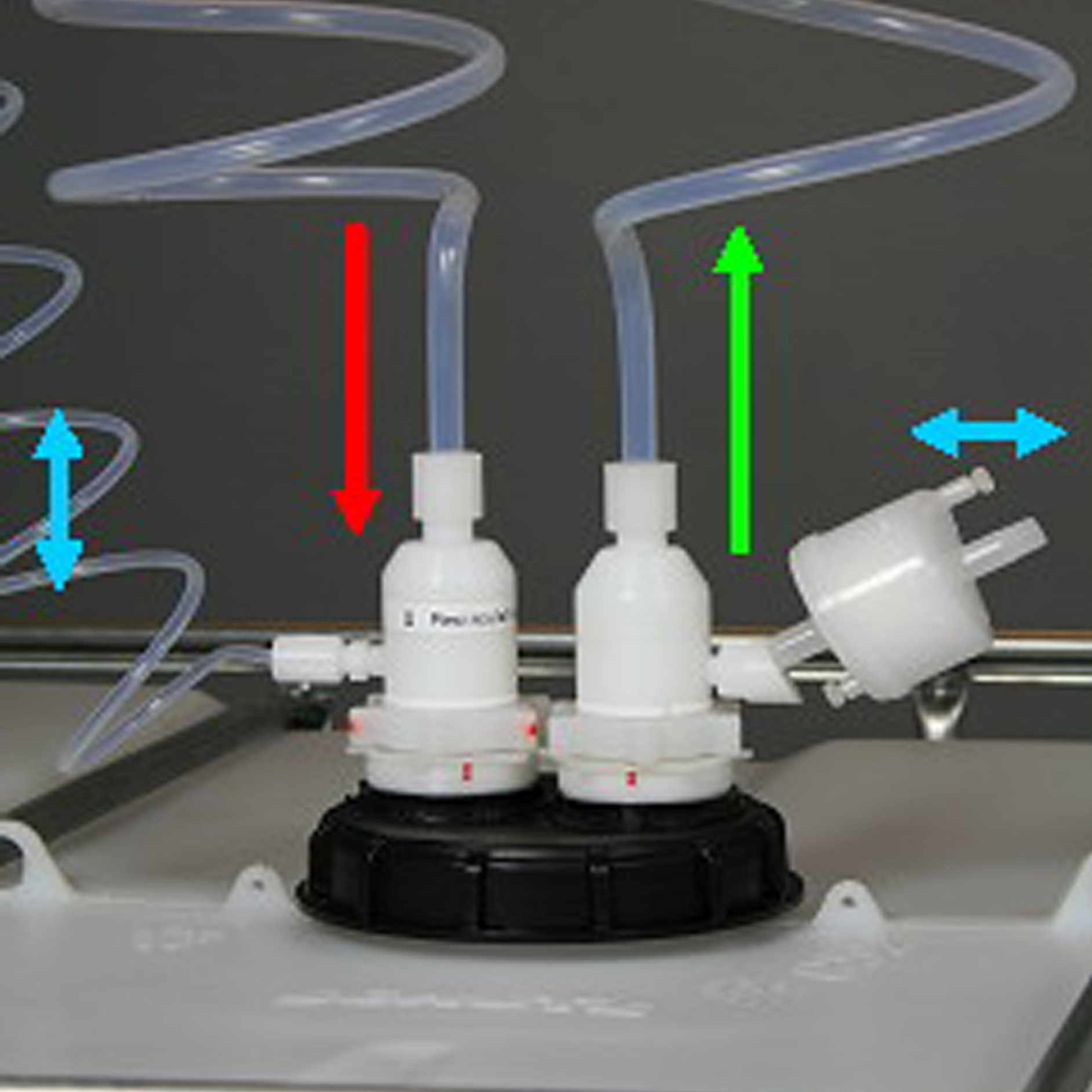

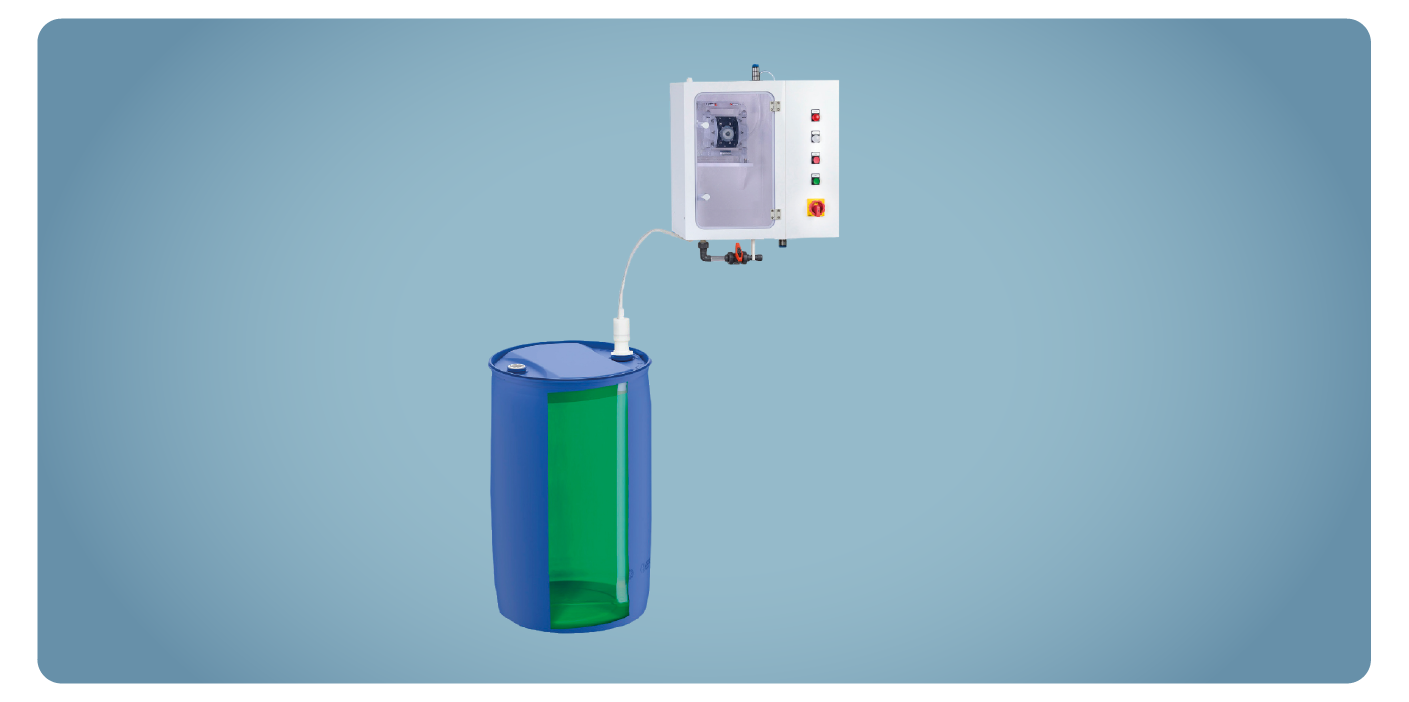

Your chemicals are delivered by the chemicals supplier with dip tubes already installed in the containers. Ensuring there is no contact with the liquid – for drip-free connection.

The consequences when handling chemicals using conventional drum pumps, self-made suction lances or even just with tubes put into the container can be serious: hazardous substances continuously outgassing, drips when inserting and removing and the ever-present risk of contact with the chemical that is always associated with injury to operators, damage to production equipment, and sometimes even leading to building damage. Even totes with integrated ball valves do not stay non-drip for ever – no wonder because even a high-grade industrial valve costs more today than a standard tote with pre-mounted valve....